How Much Does Rebar Cost per Foot in 2025?

The cost of rebar per foot is $3.65, though it can range from $.50 to $6.80depending on the type, grade, and local delivery fees.

On average, rebar costs $3.65 per linear foot.

Rebar diameter is measured in imperial bar sizes (the most common are #3 through #8).

Rebar is separated by grade, with grades 40 and 60 being the most common.

You can reduce the cost of rebar by limiting the size, using repetitive bar lengths and cutting them to your needs, and choosing carbon steel rebar.

Working with a concrete professional ensures a high-quality result and a job done right.

This article was created using automation technology and thoroughly fact-checked and edited by HomeAdvisor Editor Ryan Noonan.

Rebar’s cost per foot is $3.65 on average. But you could spend anywhere from $ $0.18 per foot for standard steel all the way up to $16 per foot for stainless steel. Your final price depends on bar thickness, corrosion resistance, and local labor rates.

By weighing variables like size, type, grade, delivery, and order quantity, you can build a realistic budget for your concrete or masonry job. Bringing in a concrete pro keeps the work on schedule and avoids costly missteps.

Rebar Cost Factors

Several details push your per-foot price up or down. Here’s how each one affects the bottom line.

Type

Carbon steel, stainless, galvanized, fiberglass, and epoxy-coated rebar all come with their own price tags and performance perks. Standard carbon steel handles most residential jobs just fine, but if you’re building in a damp or coastal spot, upgrading to galvanized or stainless steel can pay off in long-term corrosion resistance—just expect to pay more upfront.

| Rebar Type | Average Cost per Linear Foot |

|---|---|

| Carbon steel (standard) | $0.18–$6.80 per foot |

| Stainless steel | $2.50–$16 per foot |

| Galvanized | 10%–15% more than standard steel |

| Fiberglass | 20%–25% more per foot than standard steel |

| Epoxy-coated | $300–$400 per 50-lb box |

Carbon Steel

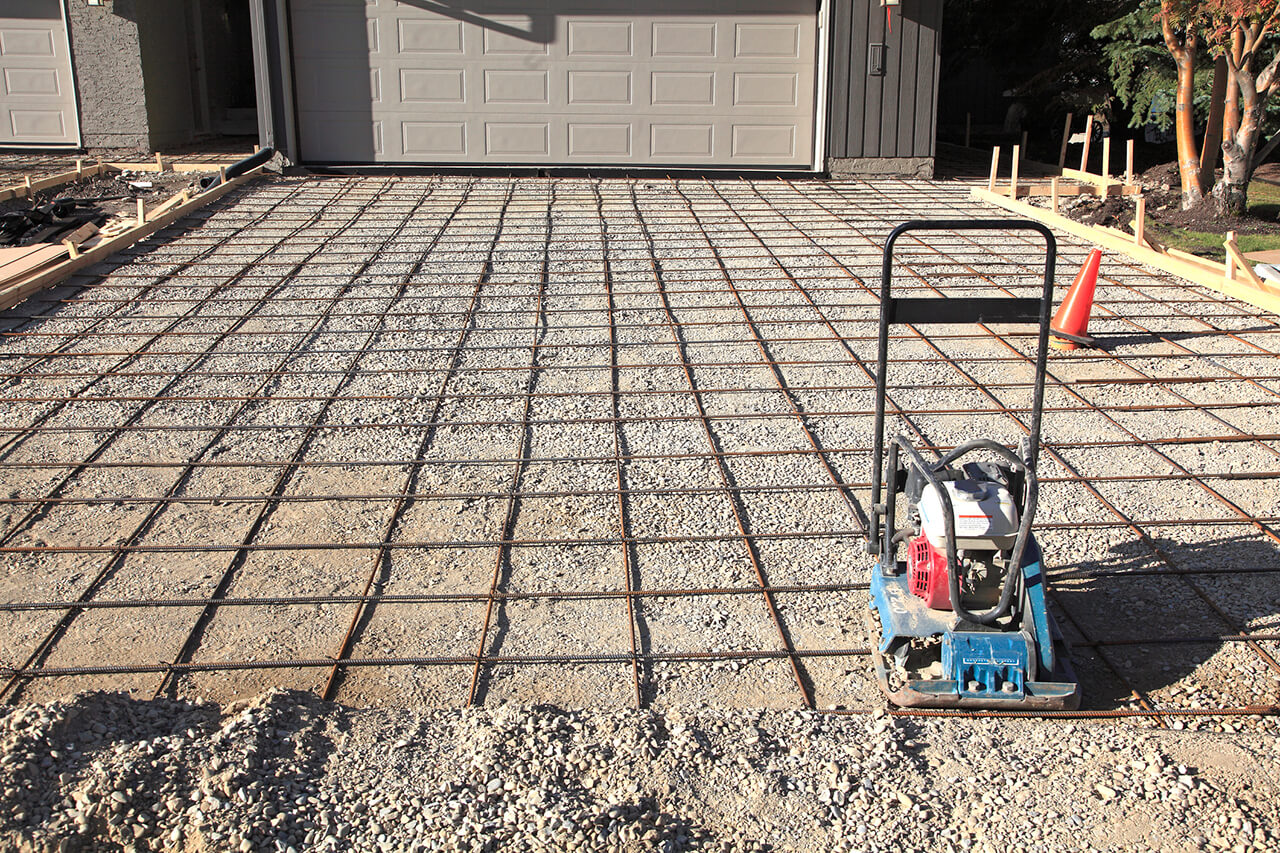

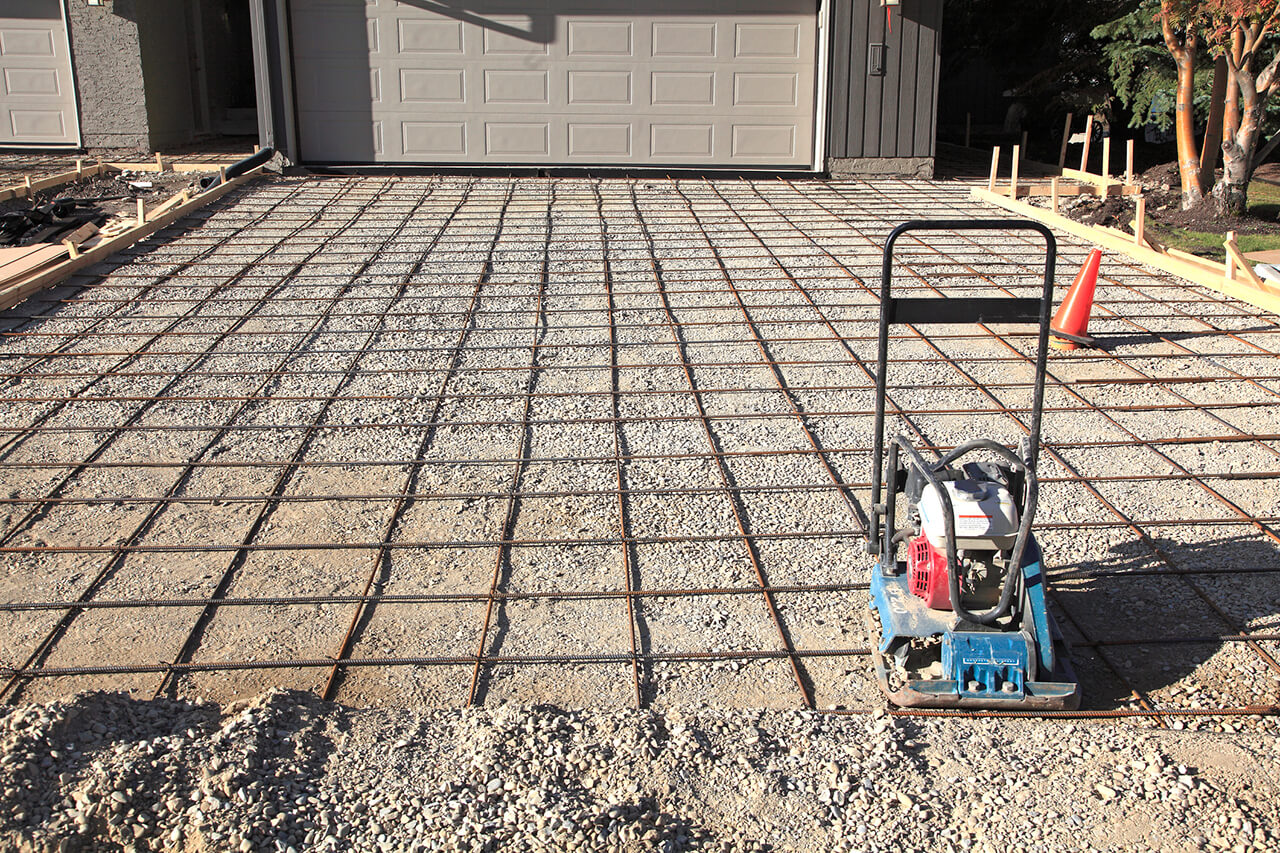

Carbon steel is the go-to choice for most jobs because it balances price and strength. At $0.18 to $6.80 per linear foot, it’s affordable, easy to cut and weld, and sturdy enough for patios, driveways, and more. The one caveat: in humid or coastal climates, the metal can rust faster than coated or stainless alternatives.

Stainless Steel

Running $2.50 to $16 per linear foot, stainless steel costs more up front but shrugs off rust, making it a smart pick for humid or coastal builds. It’s nearly maintenance-free over the long haul, though the alloy is trickier to weld than standard carbon steel.

Grade

Rebar is also labeled by grade, which tells you how much force the bar can handle before it bends (yield strength) or snaps (tensile strength). Engineers rate those limits in kilopounds per square inch (ksi), but for most homeowners the key takeaway is simple: higher grades mean stronger bars—and a higher price tag.

You’ll usually see Grade 40 or Grade 60 on residential bids. Grade 40 handles patios and light slabs, while Grade 60—about 40% pricier—steps in for thicker driveways or small structural pours. Higher grades like 75, 80, and 100 are reserved for heavy-duty commercial work.

Delivery

Rebar isn’t exactly carry-on luggage, so delivery fees can climb fast—especially on long hauls or small orders. Ask local suppliers and concrete pros for quotes; many bundle delivery into their price or can steer you toward a more affordable trucking option.

Budgeting for Rebar

Need heavier reinforcement? Mix #3 and #4 bars instead of ordering all #4s; you’ll still hit bulk-discount thresholds without overbuying.

Stick with standard 60-foot lengths where possible—repetition keeps fabrication and placement fees in check.

For irregular slabs or walls, buy stock-length bars and let the crew cut or splice them onsite instead of paying for custom lengths.

Pick the right material: standard steel suits most jobs, while galvanized, fiberglass, or stainless is worth the upgrade only when corrosion is a real threat.

DIY vs. Hiring a Concrete Pro

Because rebar is the backbone of any concrete project, a mis-cut or misplaced bar can ruin an entire pour. A seasoned pro brings the right tools and know-how, sparing you expensive do-overs and uneven slabs. Save time and stress by hiring a local concrete contractor when you’re ready to get started.

How HomeAdvisor Gets Its Cost Data

No place is more important than your home, which is why HomeAdvisor connects homeowners with local pros to transform their houses into homes they love. To help homeowners prepare for their next project, HomeAdvisor provides readers with accurate cost data and follows strict editorial guidelines. After a project is complete, we survey real customers about the costs to develop the pricing data you see, so you can make the best decisions for you and your home. We pair this data with research from reputable sources, including the U.S. Bureau of Labor Statistics, academic journals, market studies, and interviews with industry experts—all to ensure our prices reflect real-world projects.

Frequently Asked Questions

Figuring out how many bars you need isn’t a one-size-fits-all equation. A structural engineer or experienced concrete contractor will look at your slab’s thickness, the loads it must carry, and local code requirements, then run the numbers for you. That quick consultation protects your budget and keeps the finished slab safe, level, and up to code.

Match the metal to the job. For light, thin pours like a sidewalk, welded wire mesh often does the trick. Thicker slabs—driveways, garage floors, foundations—usually call for traditional steel bars. If your site sees salt, humidity, or coastal spray, spend the extra cash on galvanized or stainless steel to fend off rust and avoid future repairs. When in doubt, a concrete pro can confirm the best fit for your project and budget.

Stainless steel costs more up front, but the alloy can last 75 years or longer with little to no rust. That longevity means fewer repairs, less maintenance, and peace of mind for structures exposed to salt, moisture, or de-icing chemicals. If you’re pouring near the coast or in a humid climate, the extra dollars now can save you multiple replacements down the road.

An engineer will review the slab’s thickness, span, soil conditions, and expected loads, then specify bar size, spacing, and grade. Skipping that step or guessing can leave you with cracked concrete or a blown budget. For a modest consultation fee, a local engineer or contractor can do the math and hand you a rebar schedule that meets code and keeps your project on solid footing.